INNOVATION EXCELLENCE

Our Capabilities

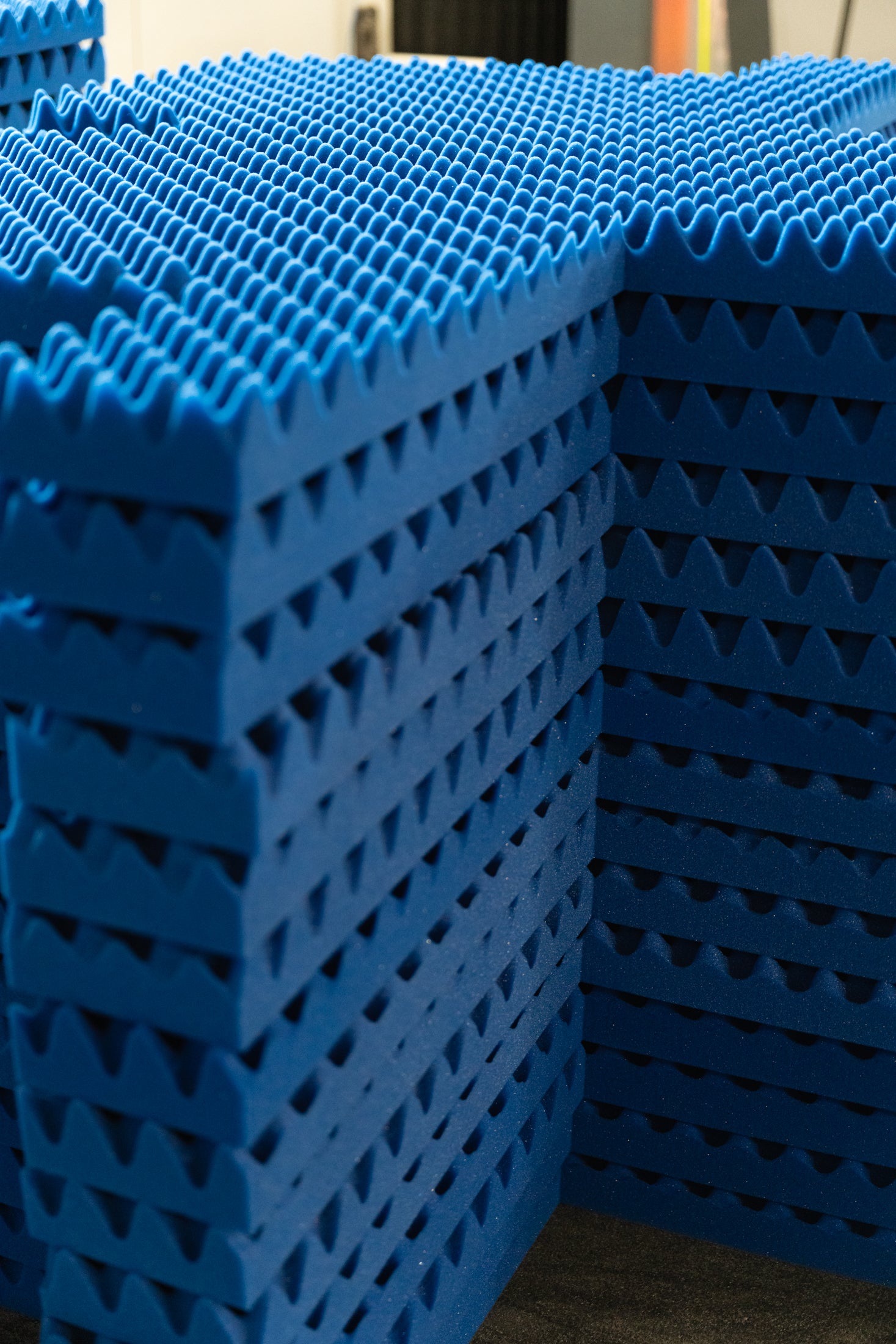

Your Foam, Your Vision: Partnering with Precision. At Envirolite, we work closely with our clients to develop innovative solutions. Our engineering team is dedicated to leveraging the latest technologies to ensure consistently reliable products. We aim to foster long-term relationships with both suppliers and customers, delivering products that provide exceptional value in the industry.

Engineered to Deliver

Materials

Our facility currently processes the following:

- Polyester polyurethane

- Polyether polyurethane

- Extruded polyethylene

- Viscoelastic memory foam

- Crosslinked EVA

- Crosslinked PE

- EPS (Expanded Polystyrene)

- Nylon fabric

- PVC vinyl

Foam Fabrication

Foam fabrication is a specialized process that transforms raw foam materials into custom shapes and products for various industries, including packaging, athletics, recreation, marine, construction, automotive, and medical applications. At Envirolite, we utilize advanced cutting, molding, and bonding techniques to create high-quality, lightweight, and durable foam solutions tailored to meet our clients’ unique needs. Our commitment to precision and sustainability ensures that every foam product we manufacture is not only effective but also environmentally responsible. Whether you need safety padding, packaging foam or custom-engineered foam components, we deliver innovative and cost-effective solutions designed for optimal performance.